In a previous post I talked about Agile frameworks, what they are, and why you should use one. The next question you should ask is “which one”, and the purpose of this series is to explain each of the most popular frameworks in a non-biased way, in an effort to answer this question. In this post, we will explore the Agile methodology of “Lean".

.

.

Lean as a philosophy has a rich history that began in the automotive industry and is now used in many manufacturing companies today spanning almost every industry. The success of Lean is undeniable and made its mark on the software world when Mary Poppendieck and Tom Poppendieck wrote the book “Lean Software Development: An Agile Toolkit”, essentially translating the Lean manufacturing principles to software development.

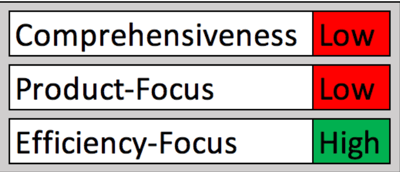

Lean is very low in terms of both comprehensiveness and product-focus, and that is kind of the point. Lean doesn’t want to tell you exactly how to do your job, or how to manage your product, relying instead on the principle that people that do the work are smart enough to define their own processes. Instead, Lean wants to create a culture of problem-solving and is very good at teaching people how to be great problem solvers by teaching them to see waste and to deal with it appropriately by solving it at the root cause. Lean provides a toolkit and mindset to use to solve problems and improve processes; some of the more well-known tools in the toolkit are “A3 Thinking”, “5 Why”, and “5S”, but this is just the tip of the iceberg.

The difference between the application of Lean in manufacturing and the application of Lean in software development comes down to differences in the guiding principles, and how “waste” is defined.

Advantages

- Proven successful at creating great processes

- Focused on shifting mindsets to a culture of problem-solving (not just a “part of the job”)

- It does not dictate how your processes should look. The advantage of this is that employees are empowered to take ownership of their own processes

Disadvantages

- Does not provide detail on how to create great products

- A large portion of Lean Transformations fail or are suboptimal

- It does not dictate how your processes should look. The disadvantage to this is that you lose out on processes that are proven to be successful

For more information about Lean, feel free to reach out to Callibrity for a consultation.